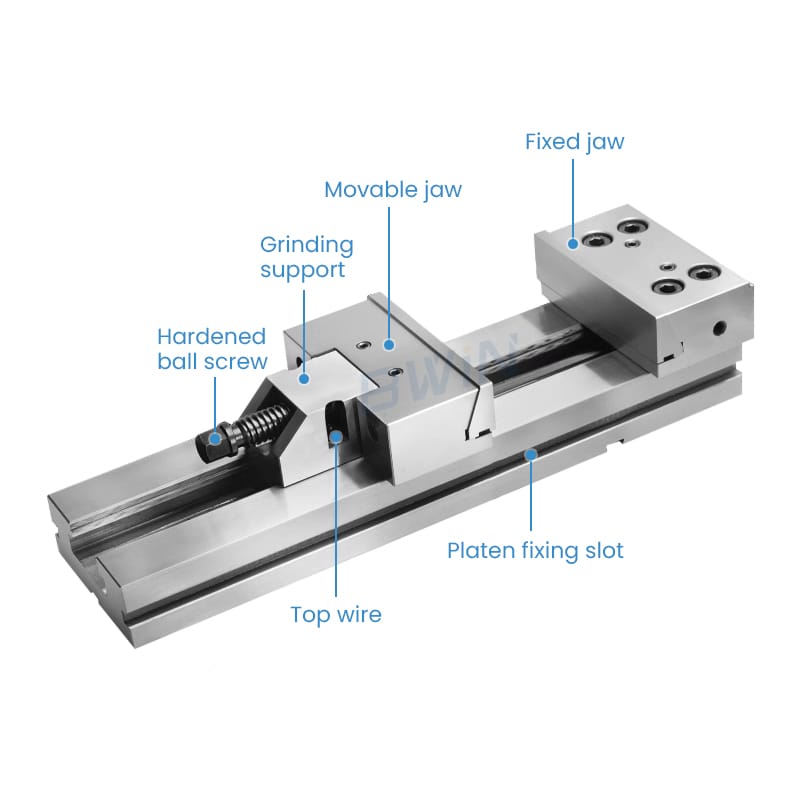

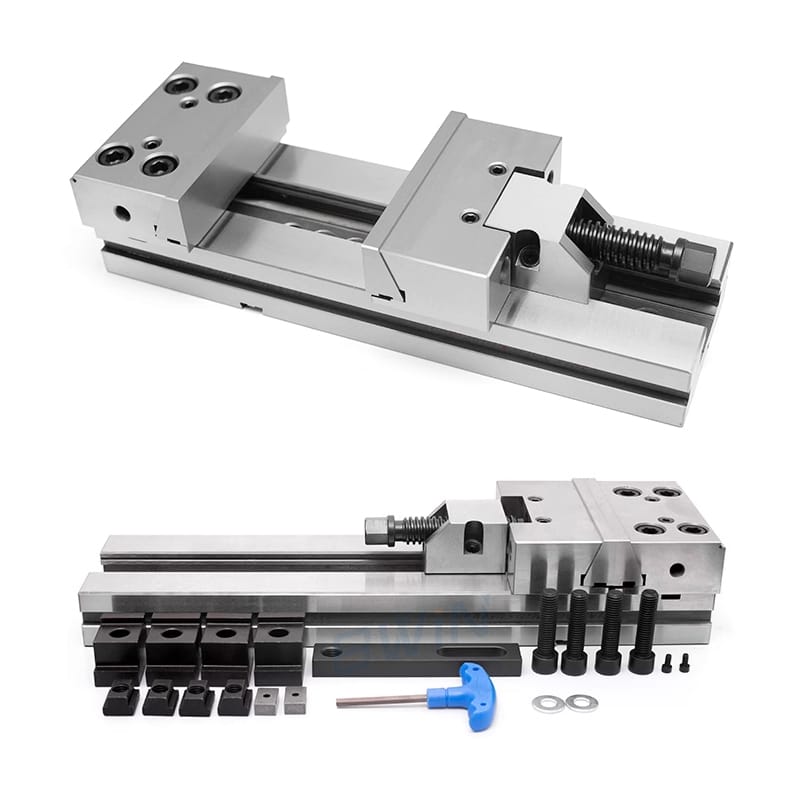

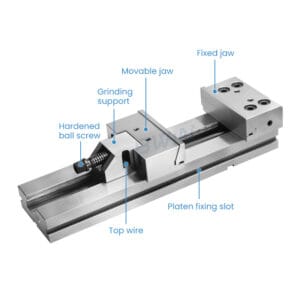

GT Precision Tool Vise

● Produced of high quality steel, carburized to surface hardness: HRC58-62.

● Parallelism 0.005mm/100mm, squareness 0.005mm.

● It have an interchangeable base, fixed/movable jaws it is quickly to clamp, and easy to operate.

● It is widely used on a machining center, and other precision machine tools.

How to :

1. Fist choose proper vise according to work-piece and locate it on the table.

2.Then let rack(03) free by loosing hex head socket set screw(04) in it.

3.Move rack(03) to have the steel ball(01) down in the set hole of the body in proper clamping position due to the size of work pieces.

4.And then drive the hex head socket set screw(04) to tighten, the steel ball(01) and hold the rack(03).

5.Put the work-piece on, turn lead screw(02) to move live jaw(08) to realize the clamping.

| Model | Vise width | Jaw height | Max. opening | Vise length | Clamping force |

| GT100 | 100 | 30 | 100 | 270 | 3000KG |

| GT125 | 125 | 40 | 150 | 345 | 3000KG |

| GT150A | 150 | 50 | 200 | 420 | 5000KG |

| GT150B | 150 | 50 | 300 | 520 | 5000KG |

| GT175A | 175 | 60 | 200 | 455 | 6000KG |

| GT175B | 175 | 60 | 300 | 555 | 6000KG |

| GT175C | 175 | 60 | 400 | 655 | 6000KG |

| GT175D | 175 | 60 | 500 | 755 | 6000KG |

| GT175E | 175 | 60 | 600 | 855 | 6000KG |

| GT200A | 200 | 65 | 200 | 495 | 10000KG |

| GT200B | 200 | 65 | 300 | 595 | 10000KG |

| GT200C | 200 | 65 | 400 | 695 | 10000KG |

| GT200D | 200 | 65 | 500 | 795 | 10000KG |

| GT200E | 200 | 65 | 600 | 895 | 10000KG |

| GT300A | 300 | 80 | 200 | 535 | 12000KG |

| GT300B | 300 | 80 | 300 | 635 | 12000KG |

| GT300C | 300 | 80 | 400 | 735 | 12000KG |

| GT300D | 300 | 80 | 500 | 835 | 12000KG |

| GT300E | 300 | 80 | 600 | 935 | 12000KG |

| GT300F | 300 | 80 | 700 | 1035 | 12000KG |

| GT300G | 300 | 80 | 800 | 1135 | 12000KG |

Reviews

There are no reviews yet.