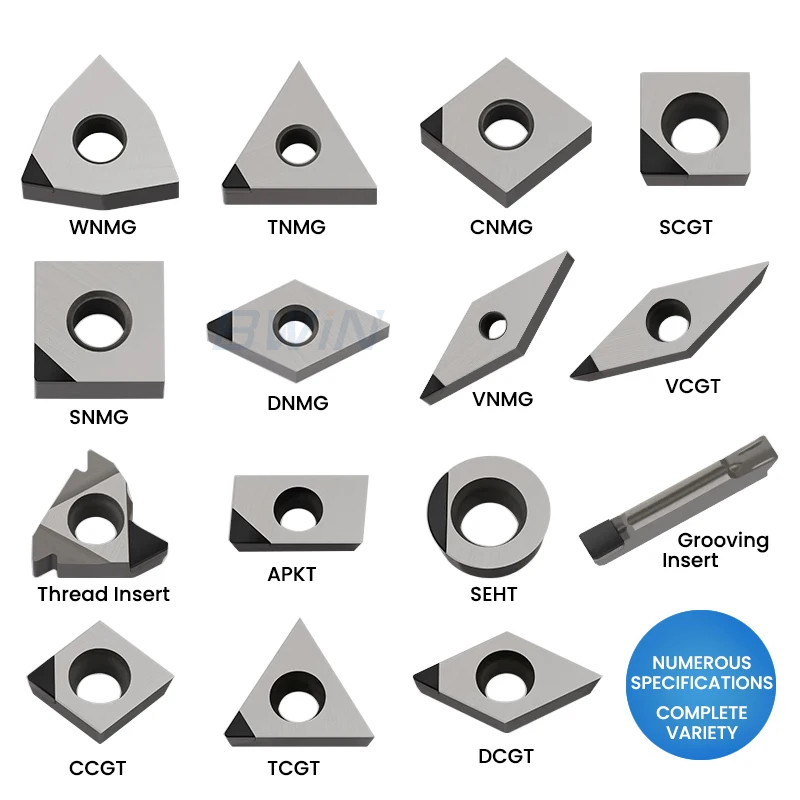

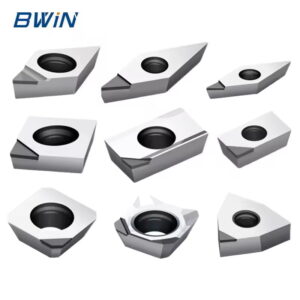

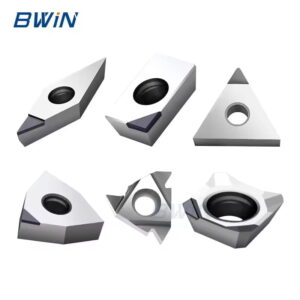

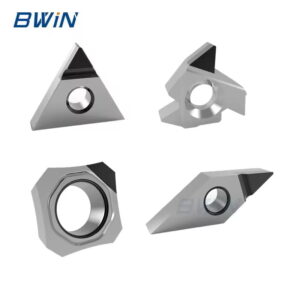

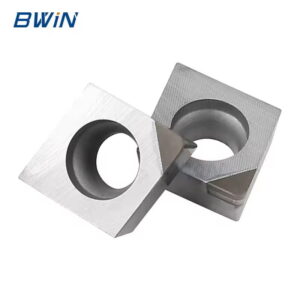

manufacturers cutting tools milling insert solid carbide turning insert pcd pcbn cbn inserts turning tools

Product name | solid carbide turning insert pcd pcbn cbn inserts turning tools |

Material | CBN +carbide |

Color | Silver |

Coating | Uncoated |

Usage | External Turning Tool / Internal Turning Tool |

Inspection | 100% |

Service | OEM/ODM |

Suitable for | Stainless steel, Steel, Hardened steel, Mould steel, Alloy steel, cast iron, aluminum, copper |

Advantage | (1) PCD composite sheet not only has excellent properties such as high diamond hardness, high wear resistance, high thermal conductivity, low friction factor, low thermal expansion coefficient, etc., but also has good strength and toughness of cemented carbide. (2) The life of PCD insert is 10~20 times that of cemented carbide, and it has super long tool life in aluminum alloy and copper alloy processing, and in non-alloy materials, such as ceramics, stone, rubber, graphite, stone, etc. Superior performance (3) It is very suitable for product finishing, and the processing effect can achieve a mirror effect. |

Package | 2pcs / box |

The key cutting products we selling as below: | |

◆ Carbide inserts ◆ Solid Carbide End Mills ◆ Turning Bar Tool ◆ Face Milling Tool | ◆ Drills & Reamers & Thread Cutters & Burrs ◆ Thread Tapper Tool ◆ CNC Chuck & Adapter ◆ Precision Tool Vise ◆ Other Accessories |

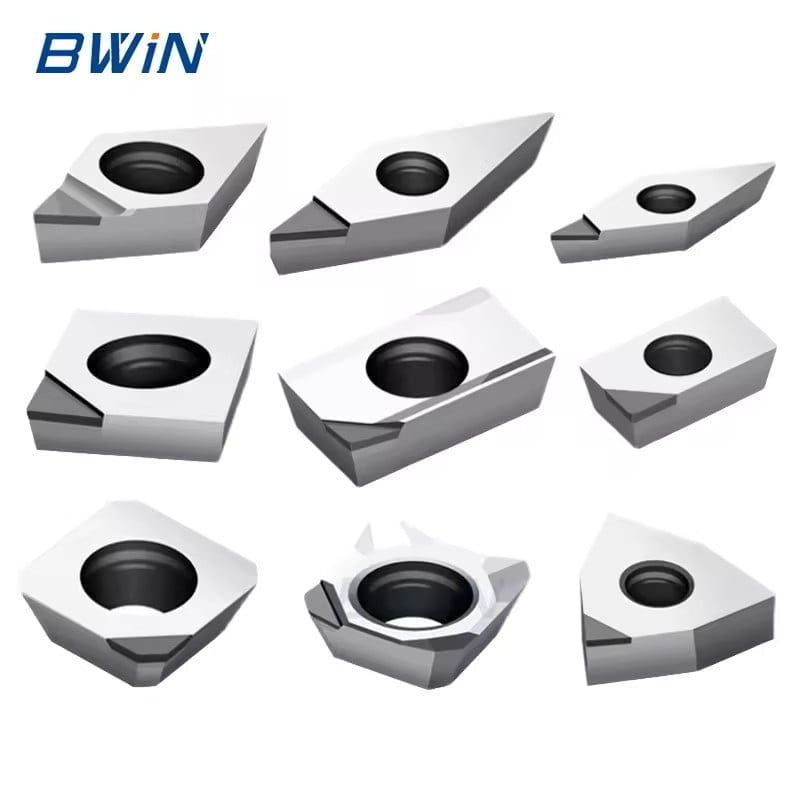

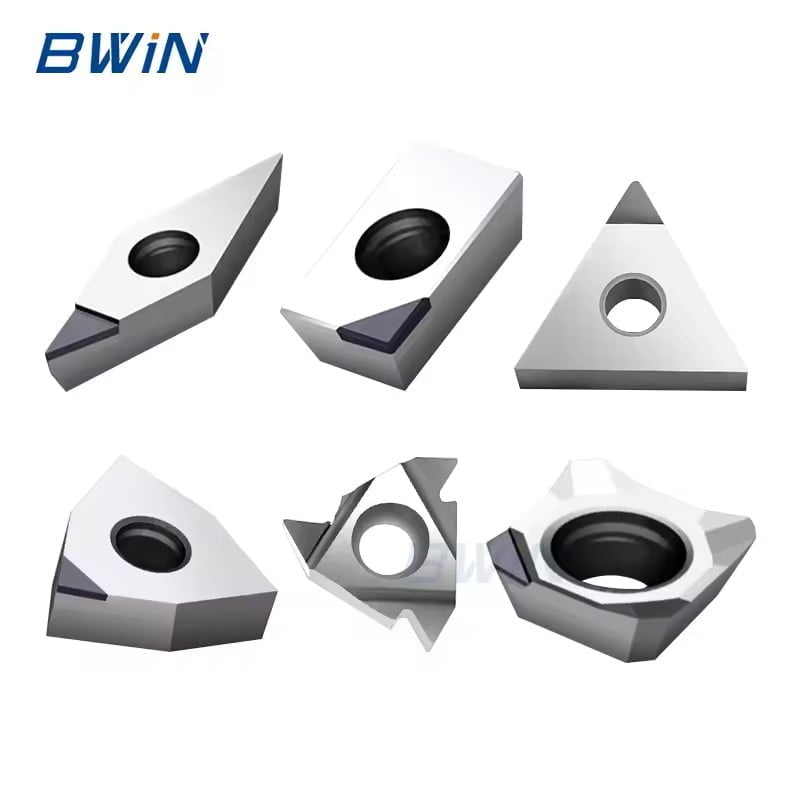

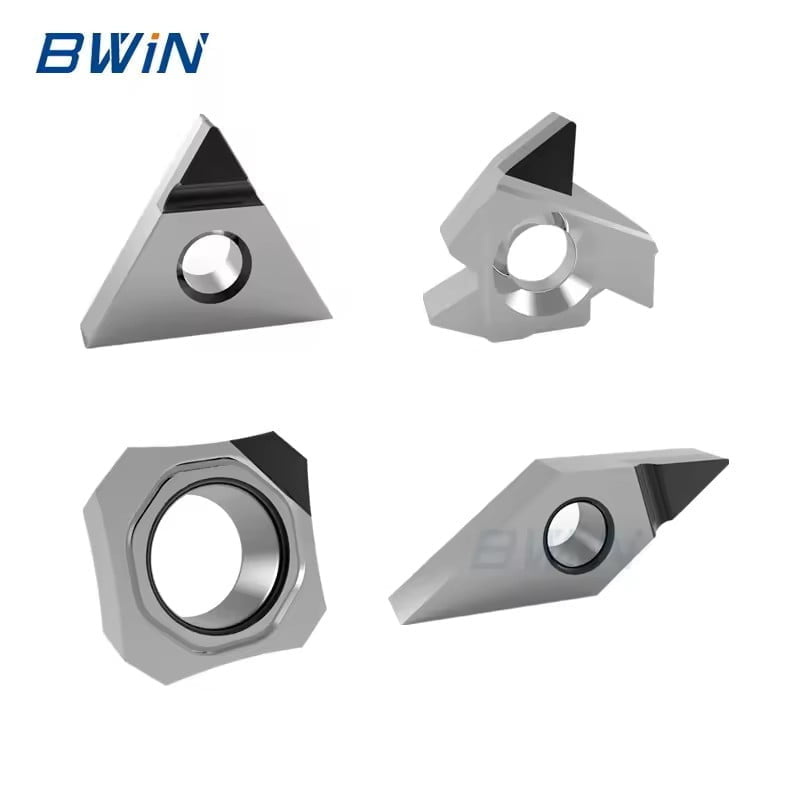

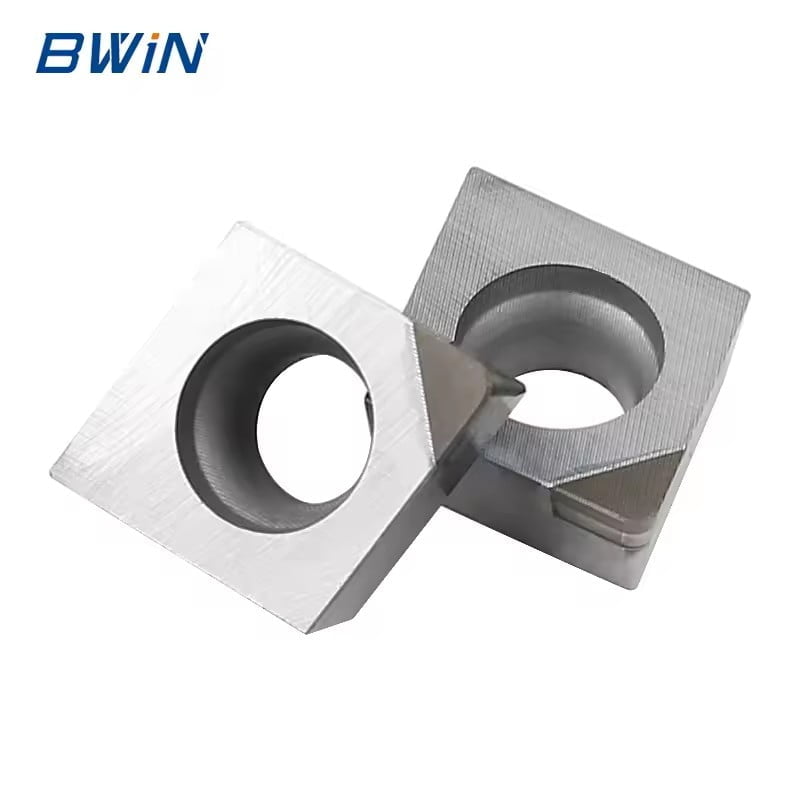

Products Show

Poly crystalline diamond (PCD) | Cubic Boron Nitride (CBN) | ||

Heat resistance (℃) | 700~800 | Heat resistance (℃) | 1400~1500 |

Compressive strength (Mpa) | 600~1100 | Compressive strength (Mpa) | 500~800 |

Fracture toughness (MPa·m1/2) | 9.0 | Fracture toughness (MPA·m1/2) | 9.0 |

Hardness | >8000HV | Hardness | 3500~5000HV |

Thermal conductivity [W/(m·K)] | 700 | Thermal conductivity [W/(m·K)] | 200~300 |

Thermal expansion coefficient (10-6/K) | 0.9~1.18 | Thermal expansion coefficient (10-6/K) | 3.5~4.8 |

Materials suitable for processing | PCD: Aluminum and its aluminum alloy, copper and its copper alloy, titanium carbide, magnesium, zine, lead and other non-ferrous metals. Glass fiber, carbon fiber reinforced plastic and other nonmetals. | ||

CBN: Very stable chemical properties for ferrous metals. It is suitable for rough and fine turning of hardened steel (HRC45~65), bearing steel (HRC60~62), high speed steel (>HRC62), tool steel (HRC57~60), chilled cast iron, and high speed cutting of superalloy, thermal spraying material, hard alloy containing Co more than 10% and other difficult materials. It can be achieved by replacing grinding with turning, greatly improving processing efficiency. | |||

Diamond tool material processing parameters are recommended | |||||

Classification | Workpiece material | Hardness | Cutting speed (m/min) | Feed rate (mm/rev) | Cutting depth (mm) |

CBN | Grey cast iron | HB170~230 | 500~1500 | 0.1~0.4 | 0.1~1.5 |

Ductile cast iron | HB240~300 | 200~400 | 0.1~0.4 | 0.1~1.5 | |

Alloy cast iron | HB240~300 | 150~300 | 0.05~0.4 | 0.1~1.5 | |

Ferrous alloy | HRC45~50 | 50~150 | 0.05~0.4 | 0.05~0.5 | |

Quenched steel | HRC45~65 | 80~200 | 0.05~0.2 | 0.05~0.2 | |

Calorite | 50~200 | 0.05~0.2 | 0.05~0.2 | ||

PCD | Aluminum alloy | 200~3000 | 0.05~0.2 | 0.05~1.0 | |

Non-metallic | 100~500 | 0.05~0.2 | 0.05~1.0 | ||

Hard alloy | 20~30 | 0.05~0.2 | 0.05~0.2 | ||

Grade for Carbide Inserts | ||||

Bwin Grade | Coating | Color | Workpiece material | APPLICATION |

BP010 | CVD | Yellow | P10-P20 | Suitable for general steel turning. |

BP020 | CVD | Yellow | P10-P20 | Suitable for semi-finishing to finishing steel machining. |

BP025 | CVD | Black | P15-P30 | Preferred grade for semi-finishing to finishing steel machining. |

BP030 | CVD | Yellow | P25-P35 | BP030 is an upgraded version of BP020,Suitable for intermittent cutting of steel. |

BP050 | CVD | Two-color | P30-P45 | It is suitable for turning of various steels and is the first choice for wear resistance. |

BT015 | PVD | Dark Gray | P20-P30 K10-K30 | Suitable for steel and cast iron slight milling. |

BT030 | PVD | Dark purple | P10-P25 M15-M35 | Suitable for steel and stainless steel continue turning and threading. |

BT065 | PVD | Yellow | P10-P20 | Good at steel semi-finishing turning, parting and grooving processing, preferred grade for steel and stainless steel milling and drilling. |

BM035 | PVD | Dark purple | M10-M30 | Good at stainless steel semi-finishing turning, parting and grooving processing, preferred grade for steel and stainless steel milling and drilling. |

BM055 | PVD | Gray | M15-M35 | Preferred grade for steel and stainless milling and drilling. |

BM085 | PVD | Colorful | M30-M55 S15-S40 H15-H55 | Newly upgraded coating technology, the new king of steel milling; Enhanced tip design, excellent impact resistance. |

BK115 | CVD | Black | K15-K30 | Suitable grade for semi-finishing to slight interrupted cast iron machining. |

Reviews

There are no reviews yet.